Features of Fiber Laser Tube Cutting Metal Machine Cuts Tubes For Steel:

1. Application of gantry structure and integrated cast cross-girder to achieve, higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating system which make the best cutting effect.

3. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The machine is used for cutting a variety of metals with excellent and stable cutting quality.

6. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

Parameters of Fiber Laser Tube Cutting Metal Machine Cuts Tubes For Steel:

Laser Type | GC-FR6020 |

Laser power | 1000W -40000W ( IPG/ MAX/ Raycus) |

Lubrication system | Full-automatic |

Pipes support mode | Three cylinders support,servo follow |

Gross weight | 3000KG |

Maximum speed | 100m/min |

Graphic Format Supported | AI,DXF,BMP,DST,DWG,DXP |

Condition | New |

Cutting Thickness | 0-30mm |

CNC or Not | Yes |

Cooling Mode | Water Cooling |

Control Software | CYPCUT |

Place of Origin | China |

Brand Name | Baisheng |

Certification | CE,ISO, |

Warranty | 3 years |

After-sales Service Provided | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support |

Applications of Fiber Laser Tube Cutting Metal Machine Cuts Tubes For Steel:

1.Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2. Application Industries: Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Warranty & Service:

1). 3 years warranty for the whole machine

2). 3years warranty for the fiber laser source

3). Life-long maintenance

4). In the warranty period,if it break down or some parts damaged(Except the human factors and the factors of force majeure),the seller should be responsible for repair for free,the parts need to be replaced will be provided from seller for free(Except the quick-wear part).

5). After warranty we will still supply lifetime maintenance in free. Just if parts broken, we will replace with charge.

6). After sales service response time: quick response within 8 working hours,after receive the repair call, our after sales engineer will reply as soon as possible.

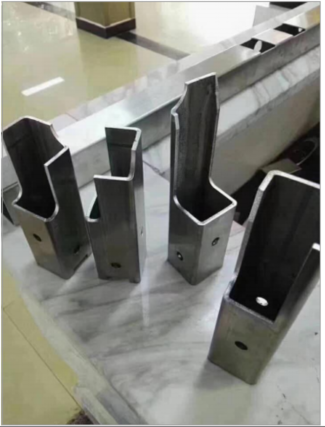

CNC metal pipe laser cutting machine is an automatic tube cutter that realizes metal tubes (square tube, round tube, rectangular tube, channel beam, flange beam, U-tube, flat tube, and all types of shaped tubes and pipes) cut with the cooperation of computer and laser generator.

CNC laser tube cutters can cut any programmed shape on metal tubes, and the laser can cut perfectly in any direction. The shape to be processed can be flexibly and quickly changed through computer programming design. The high flexibility of laser tube cutting machines provides a strong technical support for more and more personalized metal processing, thereby reducing the number of molds used.

The modular design with the CNC controller realizes the unmanned and full data production of the pipe cutting operation. Compared with traditional metal pipe cutting system such as flame cutting, plasma cutting and water jet cutting, the precision of laser-cut metal pipes is much higher.

The CNC laser tube cutting machine can be flexibly adjusted according to these deformations, which is also beyond the reach of many traditional cutting methods.

CNC laser tube cutting machine adopts centralized operation, flexible cutting, automatic loading and unloading, and the clamping is convenient and fast.

It adopts precision rack and double drive mode, which is easy to maintain and maintain, and is basically maintenance-free.

It adopts professional tube cutting software, which is the fundamental guarantee for effectively saving materials and improving cutting efficiency.

Based on these advantages, laser pipe cutting machines are widely used in the processing of round pipes, square pipes, rectangular pipes and special-shaped pipes in fitness equipment, office furniture, kitchen cabinets and other industries.